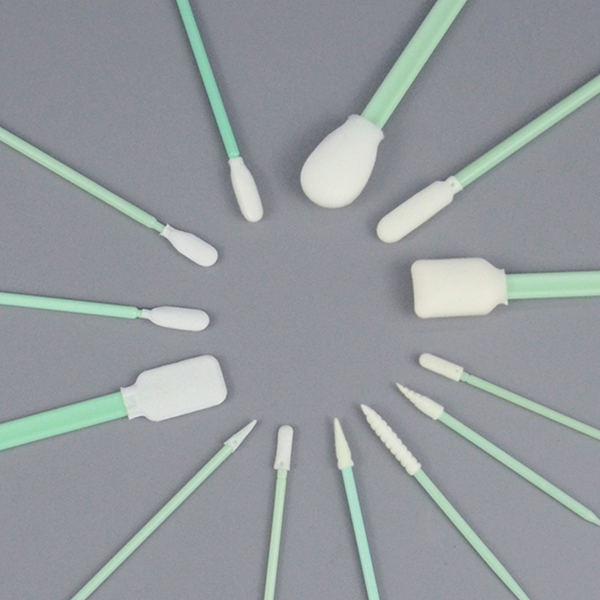

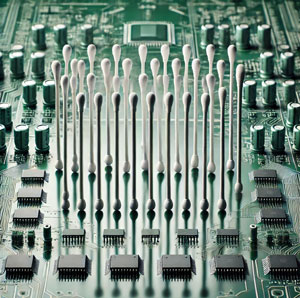

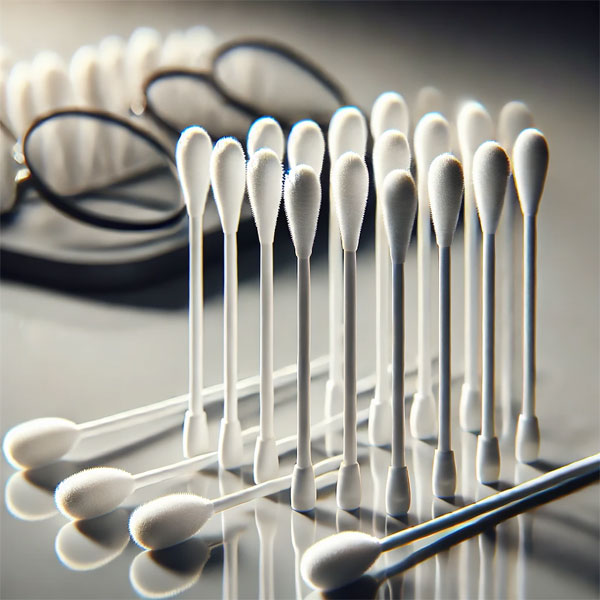

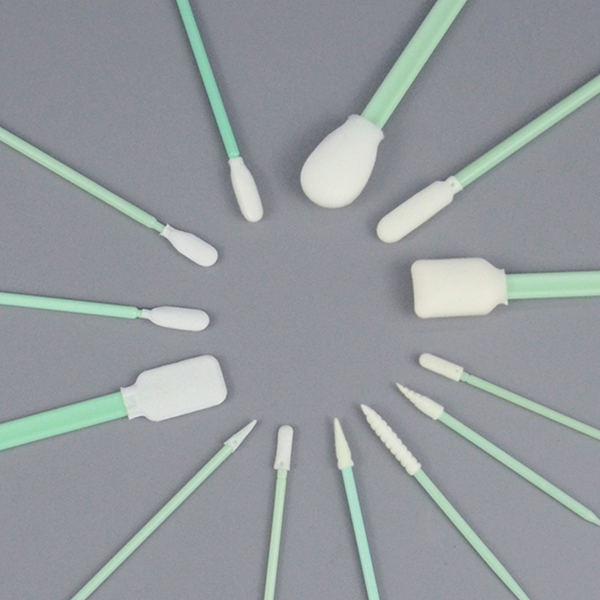

We often forget about the simple swab in our cleaning kit. Yet, it plays a big role in keeping places sterile. Places where even a tiny speck of dust could cause big problems. A lint free swab isn’t just another tool. It’s a vital helper in our fight against unseen enemies that could harm cleanroom spaces. These special swabs are made to not let go of fibers or particles during use. This is very important. It helps stop contamination in sensitive spots like aerospace factories, biotech labs, and places where medicines are made. With prices ranging from $7.99 to $709.9912, and being made in different countries like China, the USA, Japan, and Costa Rica1, it’s clear that these swabs come in many types. Each serves different needs in various industries. Key Takeaways Understanding the Basics of Lint Free Swabs When we talk about keeping places spotless, lint-free disposable swabs are key. They’re made carefully to stop tiny dust from spoiling clean areas. The Importance of Lint-Free In places like cleanrooms, even a little lint is a big problem. Lint-free swabs are crucial in stopping such dust. The PurSwab swabs are made to keep lint and residue away. They help keep clean spaces pure and work consistently. Using swabs that don’t shed, places can keep contamination low. This ensures cleanliness and steady operations. Characteristics of High-Quality Lint-Free Swabs Top-notch lint-free swabs capture particles well and are made for precision. They come in various materials like cotton and microfiber for specific needs3. Microfiber swabs, for example, are great for sensitive tasks. Foam swabs are preferred for general cleaning for their trapping and non-linting features3. Common Materials Used in Lint-Free Swabs The swabs are made from different materials to fit specific needs. Swab shafts can be wood, polypropylene, or paper, each offering unique […]

Learn More