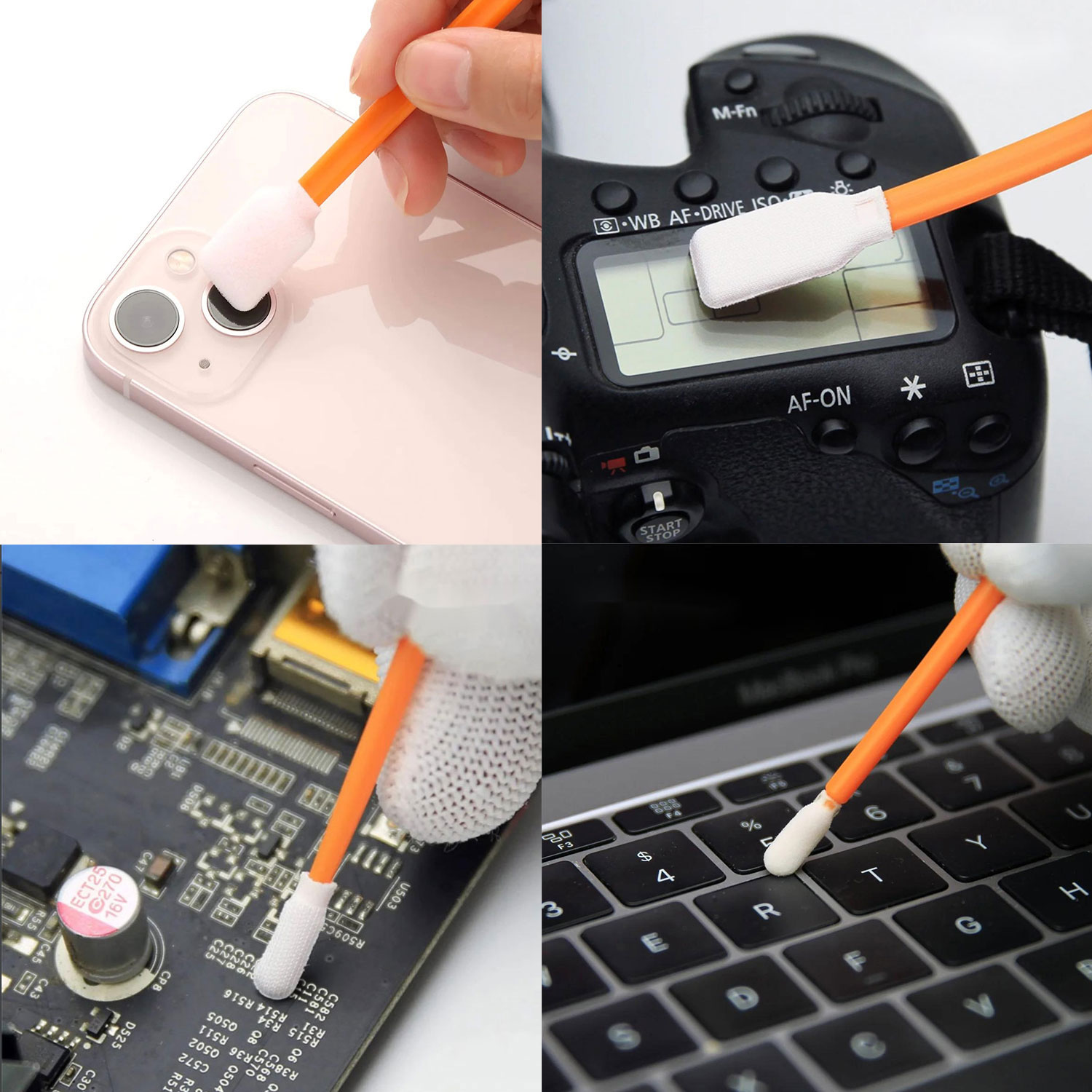

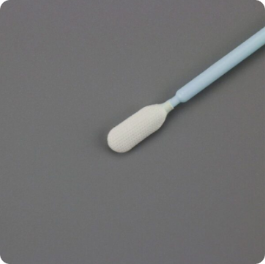

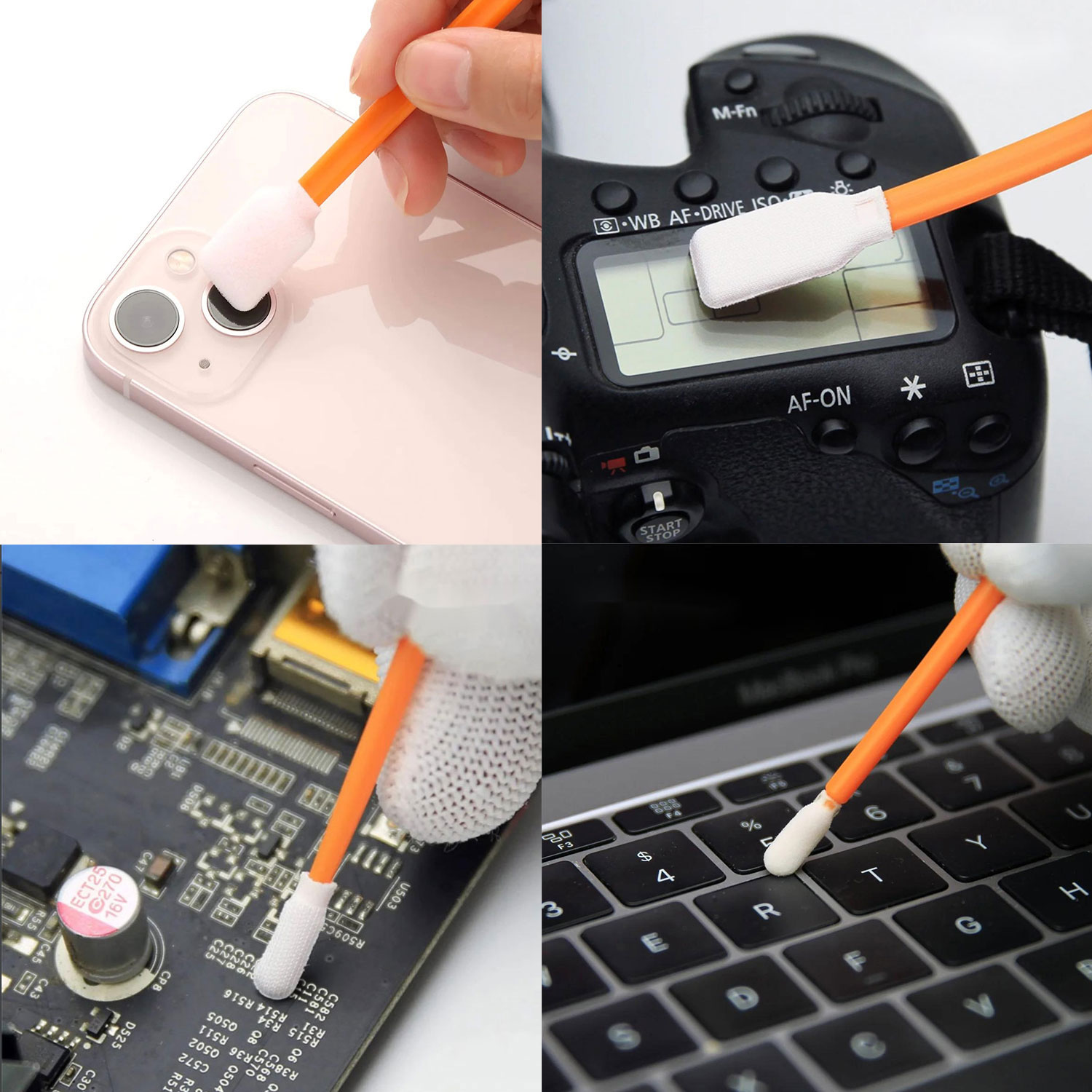

What is a cleanroom swab? Cleanroom swabs are a tool specially designed for meticulous cleaning and are widely used in situations where high cleanliness is required. Compared with ordinary cotton swabs, cleanroom swabs are made of more professional materials and designs, and can effectively remove dust, oil, and other pollutants without causing fiber shedding or pollutant residue. They are ideal for cleaning electronic equipment, optical instruments, medical devices, laboratories, and other fields. What should I look for when choosing cleanroom swabs? Cleanroom Swab Material The material of cleanroom swabs directly affects their absorbency, softness, flaking, and anti-static effect, and different materials are suitable for different applications: 1. Polyester Fiber Swabs These swabs are made up of low-lint polyester fibers that effectively remove contaminants. Pros: – Non-absorbent. – Highly resistant to most solvents – Produces fewer particles – Effectively cleans oil, dirt, and tiny particles Applications: Ideal for medical devices, electronics manufacturing, environmental laboratories, and forensic identification. 2. Foam Cleaning Swabs Swabs are made by hot fusing a high-density foam material to the swab handle. Features: – Soft, non-abrasive swab tip – Capable of absorbing large quantities of dirt, material surface stabilization – No flakes – Strong resistance to solutions, and stable performance in various environments. Applications: more suitable for deep cleaning of items requiring high cleanliness. Specialized in cleaning sensitive equipment, such as printers, microscopes, electronic equipment, optical sensors, etc. 3. Microfiber Swabs Thermally bonded microfiber polyester tips, these materials have an extremely fine fiber structure and are usually made of polyester fibers and polymers such as nylon. Features: – Soft and non-abrasive head – Excellent cleaning performance – Higher water absorption capacity – Compatible with most common solvents – High cleanliness and excellent solvent resistance make this swab ideal for effectively decontaminating surfaces and hard-to-reach areas. Applications: Suitable for use in electronic, […]

Learn More