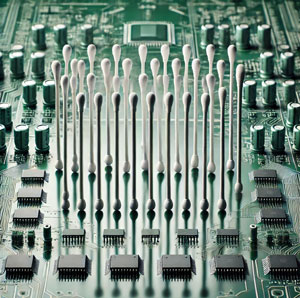

Discover how our cleaning swabs for electronics ensure precision and cleanliness for all your high-tech devices. Trust in electronic cleaning swabs.

When it comes to high-precision electronic devices, keeping them clean is critical. Cleanroom swabs are key in this process. They ensure devices work at their best, free from tiny particles that could cause harm.

These tools are made to the high standards of the tech world. They let us clean delicate parts without bringing in new dirt. This means every inch of the device stays in top condition.

Key Takeaways

● Cleanroom swabs are essential for maintaining high-precision electronic devices.

● They prevent contamination and subsequent damage to sensitive components.

● Specially designed electronic device cleaning swabs ensure optimal performance and reliability.

● Precision cleaning tools are crafted to meet stringent industry standards.

● Unique construction materials of cleanroom swabs minimize contamination risks.

Introduction to Cleanroom Swabs

Cleanroom swabs are key in places needing high precision and cleanliness. They are made to pick up tiny particles and dirt without harming delicate surfaces. These tools are crucial for making semiconductors and electronic devices. Their design fits strict cleanroom rules. Let's explore why these cleaning items are so important for keeping high-tech devices in great shape.

What Are Cleanroom Swabs?

Cleanroom swabs are made from special materials like foam, polyester, and microfiber. These materials are perfect because they don't let out particles or contaminants. This makes the swabs ideal for cleanrooms, places with rules against dust and dirt. Cleanroom swabs' main job is to ensure safe and thorough cleaning of fragile and precise parts.

Importance in High-Precision Cleaning

Keeping components clean is vital in high-tech maintenance. Cleanroom swabs do this by cleaning small, complex parts safely. They are crucial in fields like semiconductor making, where a tiny particle can cause big problems. Using cleanroom swabs keeps high-precision parts working well by preventing dirt and dust.

Types of Cleanroom Swabs for Electronic Devices

Maintaining the integrity of sensitive electronic components is key. The type of cleanroom swabs you choose is crucial. There are three main types: foam swabs, polyester swabs, and microfiber cleaning swabs. Each is suited for different electronic cleaning tasks.

Foam Swabs

Foam swabs are great for general cleaning. They are very absorbent. This makes them perfect for electronic cleaning where more absorption is needed. Their open-cell structure traps contaminants well. This ensures surfaces are left clean.

Polyester Swabs

Polyester swabs are strong and produce few particles. This makes them ideal for cleaning in controlled environments. They are effective for electronic cleaning that needs precision. They're made tough for repeated use.

Microfiber Swabs

Microfiber cleaning swabs are soft and clean effectively. They are good for cleaning delicate surfaces and components. They excel in electronic cleaning by trapping dust and debris. This ensures that sensitive parts are protected during cleaning.

| Type of Swab | Key Characteristics | Best Use-Case |

| Foam Swabs | High absorbency, versatile | General cleaning, high absorbency needs |

| Polyester Swabs | Durable, low particle generation | Critical environment cleaning |

| Microfiber Swabs | Soft, effective at trapping dust | Delicate surfaces and components |

Importance of Cleanroom Standards

The importance of following cleanroom rules is really big. In making high-precision electronic devices, it's key to keep the area free from dirt and dust. This makes sure the products work well and last a long time.

Knowing about different contamination control standards is essential. These standards explain how clean things need to be. They help decide how to clean things, including which swabs to use.

Cleanroom certification is crucial. It confirms that a cleanroom meets tough standards set by regulators. This process makes sure the area stays clean, lowering contamination risks.

We will now compare different contamination control standards:

| Standard | Description | Application |

| ISO 14644 | International standard for cleanroom classifications | Widely used in electronics, pharmaceuticals, and biotechnology |

| GMP (Good Manufacturing Practice) | Regulatory guidelines for ensuring quality and purity | Critical in pharmaceutical and biotech manufacturing |

| FS209E | US Federal standard for cleanroom cleanliness | Primarily used in military and aerospace applications |

Following these control standards, manufacturers ensure their electronic products are reliable. Cleanroom compliance is key to quality assurance in precise settings.

The Science Behind Cleanroom Swabs

The science of cleanroom swabs is key to keeping environments free of contaminants. Choosing the right cleanroom swab materials and being precise in the swab production process is vital. This ensures the swabs are reliable for use in precise settings.

Materials Used

Cleanroom swabs use special materials like laundered polyester, foam, and microfiber. Laundered polyester doesn't lint, making it perfect for delicate surfaces. Foam is great at soaking up substances, and microfiber cleans like no other. Each material helps cut down on unwanted particles and resists chemicals well.

Manufacturing Process

Making swab production starts with cutting materials to the right sizes. Then, they are thoroughly washed with de-ionized water to remove impurities. Finally, each swab goes through tight quality checks. This is to make sure they meet the high standards for cleaning in critical areas.

Applications in the Electronics Industry

Cleanroom swabs are essential in electronics, especially for precise tasks. They keep the environment clean. This ensures the reliability and efficiency of electronic parts.

Common Use-Cases

Cleanroom swabs are crucial for cleaning electronic gear. They remove dust and other particles from sensitive areas. Uses include:

● Cleaning circuit boards

● Maintaining semiconductor equipment

● Wiping down LCD screens and optics

Specialized Applications

In specialized settings, cleanroom swabs are vital. They are necessary in microelectronics manufacturing for precision cleaning. Optical product cleanrooms also rely on them to keep lenses and other components clean for the best performance.

Here's a closer look at how cleanroom swabs are used in electronics:

| Application Area | Use-Case | Benefits |

| Circuit Boards | Removing flux and residues | Prevents short circuits |

| Semiconductor Manufacturing | Cleaning wafers and equipment | Ensures product quality |

| Optical Products | Polishing and cleaning lenses | Maintains clarity and precision |

Benefits of Using Cleanroom Swabs

In the electronics industry, keeping high-quality standards is key. Using cleanroom swabs is crucial for this. These swabs are great for cleaning and making sure products work well and are reliable.

Efficiency in cleaning

Cleanroom swabs use special materials for top-notch cleaning. They get rid of particles and dirt from tough spots. This means no harm is done to electronic parts.

Brands like Berkshire Corporation and Texwipe make swabs that barely leave any residue. This is perfect for keeping electronic components safe and clean.

Minimizing Contamination Risks

Lowering contamination risks is super important in making electronics. Contaminants can mess up parts or cause the whole system to fail. Cleanroom swabs play a big role in reducing these risks.

They help make sure every device meets tough quality standards. This keeps our electronics safe and dependable.

Cleaning Swabs for Electronics

Cleanroom swabs are key in electronic cleaning. They meet the high standards needed for cleaning delicate electronic parts. Choosing the right swab is crucial for keeping devices working well.

Cleanroom swabs are super versatile. They're used for regular maintenance, fixing problems, and precise tasks like soldering. They remove dust and residue brilliantly, stopping any malfunctions.

Precision is the name of the game when it comes to using electronic cleaning tools.

Let's compare different types of swabs:

| Type of Swab | Best Use | Advantages |

| Foam Swabs | General Cleaning | Highly absorbent, durable |

| Polyester Swabs | Sensitive Components | Low particle generation, solvent-resistant |

| Microfiber Swabs | Microelectronics | Excellent particle removal, soft touch |

Picking the right swab for electronic cleaning is essential. Every swab type has special strengths for certain jobs. It's important to choose based on what you need for your electronic items.

How to Choose the Right Cleanroom Swab

When you need to pick a cleanroom swab, think about a few key points. Consider the type of dirt, how sensitive the surface is, and how much you need to soak up. These factors are big in choosing correctly.

Factors to Consider

Picking the best swab means looking at several important factors:

● Contaminant Type: Different kinds of dirt need different swab materials to be removed well.

● Surface Sensitivity: Some surfaces can scratch easily and require gentler swabs.

● Absorption Needs: For soaking up liquids, use highly absorbent swabs. Other swabs are good for dry cleaning.

Comparison of Different Swabs

Comparing cleanroom swab types helps find the right one for what you need. Below is a simple guide to the different swabs:

| Swab Type | Material | Best For | Characteristics |

| Foam Swabs | Polyurethane foam | General cleaning and liquid absorption | High absorbency, soft texture |

| Polyester Swabs | Knitted polyester | Tougher cleaning tasks | Durable, low particle generation |

| Microfiber Swabs | Microfiber weave | Cleaning sensitive surfaces | Highly effective in particle removal, soft |

Selecting cleanroom swabs wisely and knowing their properties ensures effective cleaning. It protects your sensitive electronic devices.

Quality Assurance and Certifications

In electronics manufacturing and maintenance, ensuring quality is crucial. Our cleanroom swabs go through thorough testing to meet the top standards. Thanks to international certifications like ISO and CE markings, we achieve this goal. They help us prove our swabs are reliable and high quality.

ISO Certifications

ISO certifications show our dedication to quality. For instance, the ISO 14644 certification means our swabs have minimal contamination. We follow strict rules to make sure our swabs clean electronic parts well. Adding these certifications shows we care about excellence and satisfying our customers.

CE Markings

CE markings are key for meeting European safety and health standards. They prove our commitment to making safe, reliable cleanroom swabs. When clients see the CE mark, they know our products are trustworthy. This reflects our dedication to high standards in producing cleanroom swabs.

FAQ

What Are Cleanroom Swabs?

Cleanroom swabs are made for cleaning in high-tech areas. They come from materials like foam and microfiber. These tools don’t release any particles, keeping sensitive areas clean.

Why Are Cleanroom Swabs Important in High-Precision Cleaning?

They are key for cleaning where precision is critical. Swabs prevent contamination, avoiding damage and inefficiency. They help electronic devices work properly for longer.

What Are the Different Types of Cleanroom Swabs for Electronic Devices?

Our swabs come in various kinds for different needs.

● Foam swabs are super absorbent for general use.

● Polyester swabs are strong and keep particles low for critical areas.

● Microfiber swabs are soft but effective on delicate surfaces.

How Do Cleanroom Standards Affect Swab Usage?

Following cleanroom standards keeps electronic device-making areas contaminant-free. Standards guide how to pick and use swabs properly.

What Materials Are Used in Cleanroom Swabs?

Swabs are usually made from polyester, foam, and microfiber. These are chosen for their no-lint and chemical resistance, perfect for clean cleaning.

How Are Cleanroom Swabs Manufactured?

Making swabs involves careful material cutting, washing in clean water, and strict quality checks. This ensures every swab meets critical cleaning standards.

What Are Some Common Cases for Cleanroom Swabs in the Electronics Industry?

They're used for maintenance and preparing components in electronics. Cleanroom swabs make sure every surface is particle and film-free for best performance.

Are There Specialized Applications for Cleanroom Swabs?

Yes, swabs are also crucial in making optical and microelectronics. Their precision use keeps electronic products reliable and efficient.

What Are the Benefits of Using Cleanroom Swabs?

These swabs boost cleaning effectiveness and don’t leave residues. This reduces contamination risks, helping maintain product quality.

How Do I Choose the Right Cleanroom Swab?

To pick the right swab, consider the contamination type, surface's sensitivity, and absorption need. Exploring various swab types helps us understand their unique advantages.

What Are ISO Certifications and CE Markings?

These are quality marks for cleanroom swabs, showing they meet international standards. They prove the swabs are reliable for precise cleaning needs in electronics.