What is a cleanroom swab?

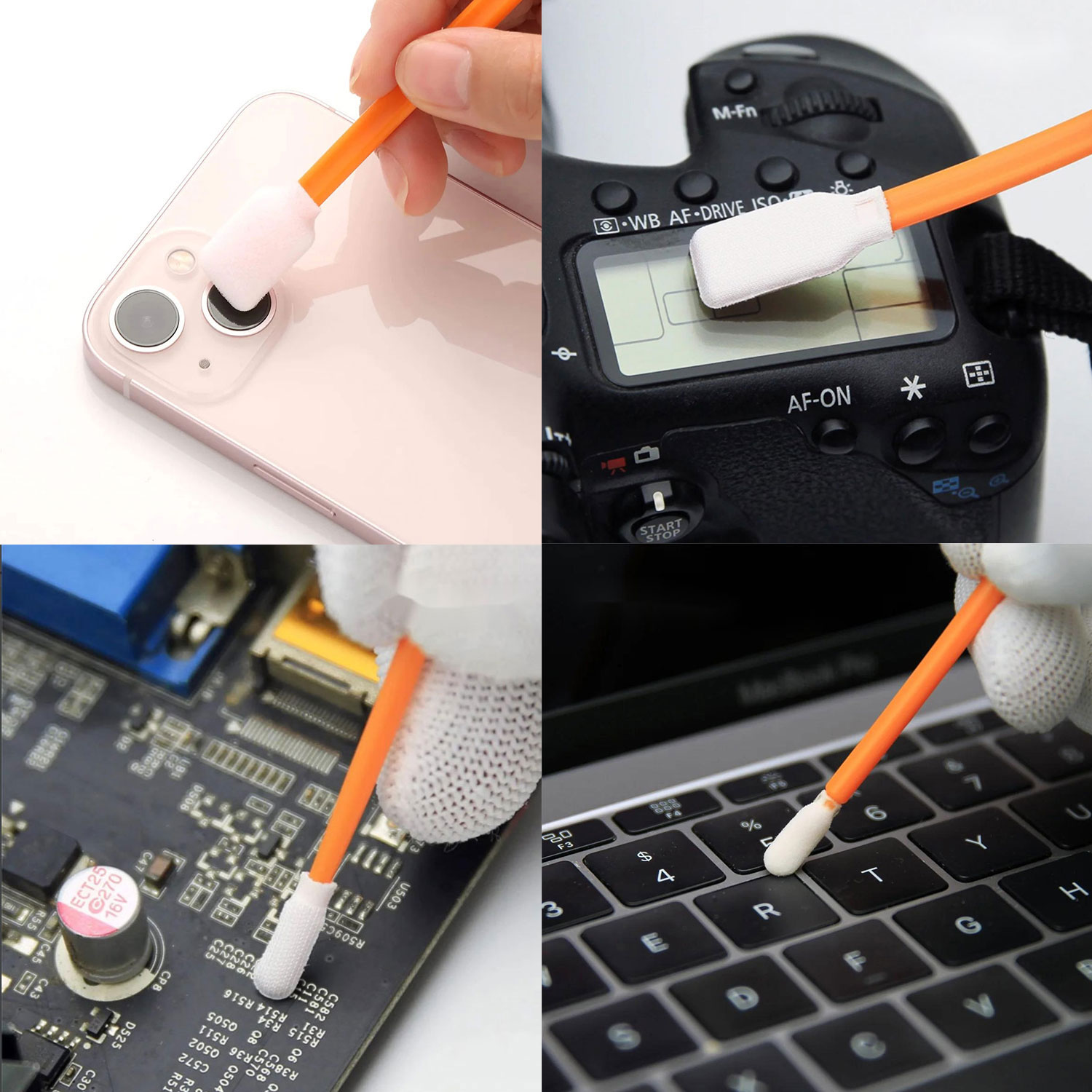

Cleanroom swabs are a tool specially designed for meticulous cleaning and are widely used in situations where high cleanliness is required.

Compared with ordinary cotton swabs, cleanroom swabs are made of more professional materials and designs, and can effectively remove dust, oil, and other pollutants without causing fiber shedding or pollutant residue.

They are ideal for cleaning electronic equipment, optical instruments, medical devices, laboratories, and other fields.

What should I look for when choosing cleanroom swabs?

Cleanroom Swab Material

The material of cleanroom swabs directly affects their absorbency, softness, flaking, and anti-static effect, and different materials are suitable for different applications:

1. Polyester Fiber Swabs

These swabs are made up of low-lint polyester fibers that effectively remove contaminants.

Pros:

- Non-absorbent.

- Highly resistant to most solvents

- Produces fewer particles

- Effectively cleans oil, dirt, and tiny particles

Applications: Ideal for medical devices, electronics manufacturing, environmental laboratories, and forensic identification.

2. Foam Cleaning Swabs

Swabs are made by hot fusing a high-density foam material to the swab handle.

Features:

- Soft, non-abrasive swab tip

- Capable of absorbing large quantities of dirt, material surface stabilization

- No flakes

- Strong resistance to solutions, and stable performance in various environments.

Applications: more suitable for deep cleaning of items requiring high cleanliness. Specialized in cleaning sensitive equipment, such as printers, microscopes, electronic equipment, optical sensors, etc.

3. Microfiber Swabs

Thermally bonded microfiber polyester tips, these materials have an extremely fine fiber structure and are usually made of polyester fibers and polymers such as nylon.

Features:

- Soft and non-abrasive head

- Excellent cleaning performance

- Higher water absorption capacity

- Compatible with most common solvents

- High cleanliness and excellent solvent resistance make this swab ideal for effectively decontaminating surfaces and hard-to-reach areas.

Applications: Suitable for use in electronic, optical, medical, and clean environments.

4. Static Control

The swab head and rod are made of anti-static material to effectively prevent static buildup.

Features:

- Insulated and anti-static

- Low flaking

- Chemical resistant

Applications: Ideal for use in cleanrooms, semiconductor manufacturing, precision electronics, and optical equipment.

5. Gel Swabs

Swabs formed by coating the swab head with gel enable high-precision cleaning tasks.

Features:

- Anti-static

- Low flaking

- Chemical resistant

- Gentle protection

- Multi-functional

6. Non-woven Swabs

These are swabs made up of soft non-woven fabrics, generally put together by heat pressing or chemical bonding of the fibers to form a fabric, and use these fabrics with a swab stick to form a non-woven swab.

Features:

- Better water absorbency

- Low particulate matter

- Resistant to a wide range of chemical solvents

- Soft and comfortable

- Aseptic

- Biodegradable material

Swab Tip Designs

There are a variety of swab tip designs to suit different cleaning needs. Pointed tips are ideal for cleaning small crevices and hard-to-reach areas, while rounded tips are more suitable for wiping large surfaces.

For fast, even cleaning of large surfaces, use flat-tipped swabs to attract dust and liquids, ensuring better cleaning results.

Low Particle Generation

The absence of debris during the use of cleanroom swabs is critical for high-cleanliness locations. Choose swabs that produce the least amount of particles or fibers during use.

Polyester or microfiber swabs keep fibers in place during the cleaning process, preventing tiny fibers from remaining on equipment surfaces.

Compatibility and Chemical Resistance

In many work situations where swabs must be paired with solvents for cleaning, material compatibility and chemical resistance an important factors in choosing a swab.

Polyester fibers are suitable for good resistance to various chemical solvents (e.g. isopropyl alcohol, alcohol). Foam cleaning swabs are suitable for deep cleaning when paired with solvents such as isopropyl alcohol.

Usage Scenarios

Cleanroom swabs are used in a variety of industries and fields, including electronics, semiconductor manufacturing, optical equipment, medical devices, and daily industrial cleaning.

Electronic products, semiconductor manufacturing: usually used to clean circuit boards, sensors, chips, and other precision originals, requiring swabs with static discharge and low particle characteristics.

Optical equipment: to clean sensitive surfaces such as lenses, displays, etc., choose soft materials, that do not fall off, and do not damage the surface.

Medical and Laboratory: Cleaning of various instruments and equipment to ensure sterility and infection-free.

Cleaning Environment

Different cleanroom levels have different requirements for swabs. In regular industrial environments, swabs are mainly used for daily surface cleaning, dust removal, and solvent wiping to fulfill general cleaning tasks.

In cleanrooms and clean rooms, especially Class 10 cleanrooms, the cleanliness requirements for swabs are extremely high and the tolerance for particle contamination is very low.

It is necessary to use clean swabs that meet high cleanliness standards to ensure that they do not contaminate the environment.

How to choose a cleanroom swab and its application?

1. Electronic Cleaning

| Cleaning tasks | Items | Suitable types | Instructions |

| Electronic ports and small crevices | Headphone jacks, charging ports, USB ports, etc. | Polyester Fiber Swabs | Polyester swabs are suitable for cleaning hard-to-reach electronic ports and small crevices. |

| Cleaning touchscreens and monitors | Cell phone screens, laptop monitors, game console screens, etc. | Foam Cleaning Swabs, Gel Swabs | Foam cleaning swabs and gel swabs are suitable for gently cleaning touchscreens or monitors and removing grease and dirt. |

| Precision equipment (e.g. circuit boards, memory sticks) | Circuit boards, memory sticks, hard disks, computer motherboards, etc. | Static Control Swabs | Static control swabs prevent static buildup and protect precision equipment from damage. |

2. Fiber optic cleaning

| Cleaning tasks | Items | Suitable types | Instructions |

| Cleaning of fiber optic connector end faces | Fiber optic connector end faces, jacks | Microfiber Swabs | Microfiber material, low flaking, suitable for removing tiny particles and dust, ensuring a clean end face. |

| Remove static electricity from fiber optic | Static-sensitive fiber optic device end face | Static Control Swabs | The anti-static design effectively prevents static build-up and protects fiber optic end faces from static damage. |

| Cleaning connector inner wall | Fiber optic connector inner wall, jack | Fiber Optic Cleaning Wand | Designed for fiber optic end faces and inner walls, it can penetrate into small spaces and remove dust thoroughly. |

| Quickly removes surface oil and dust | Fiber optic end faces and surrounding surfaces | Fiber Optic Cleaning Paper | Low flaking, no residue, fast cleaning of oil and dust, suitable for daily cleaning and maintenance. |

3. Cosmetics and personal care

| Cleaning tasks | Items | Suitable types | Instructions |

| Cleaning cosmetic applicators | Cosmetic brushes, puffs, sponges | Microfiber Swabs | Highly absorbent, gently removes residual cosmetic powders or oils without leaving residue. |

| Correcting make-up details | Eyeliner, lipstick, eyebrows | Cotton Swabs, Fine-tipped Cotton Swabs | Fine-tipped cotton swabs are designed for precise correction of makeup imperfections, such as removing excess eyeliner or lipstick. |

| Cleaning small, hard-to-reach areas | Ear piercings, nose, nail edges, etc. | Microfiber Swabs, Foam Cleaning Swabs | Microfiber is ideal for cleaning small areas, while foam cleaning swabs are soft and absorb excess oil and dirt. |

| Cleansing and applying skin care products | Application of skin care products such as essence and lotion. | Foam Cleaning Swabs | Soft, non-irritating, even application of skincare products, avoiding direct hand contact. |

| Remove makeup and clean stubborn stains | Lip and eye makeup, stubborn stains | Foam Cleaning Swabs, Gel Swabs | Foam cleaning swabs for gentle makeup removal and gel swabs to remove stubborn makeup without damaging the skin. |

4. Cars and car care

| Cleaning tasks | Items | Suitable types | Instructions |

| Cleaning small interior details | Air conditioning vents, dashboard buttons, crevices | Polyester Fiber Swabs, Microfiber Swabs | Polyester and microfiber swabs are low-dusting and suitable for cleaning small crevices and fine areas. |

| Remove fingerprints and smudges from interior screens | Center screens, mirrors, dashboard screens | Foam and Gel Swabs | Foam and gel swabs are soft and gentle, won't scratch the screen, and remove grease and fingerprints well. |

| Remove Stubborn Dirt | Headlight surfaces, door handles, emblems | Microfiber Swabs | Highly absorbent, suitable for cleaning stubborn stains on the car body, especially in hard-to-reach details. |

| Cleaning of car electronics | Navigation devices, instrument panels, electronic components | Static Control Swabs | Anti-static design protects electronic equipment from static damage during cleaning. |

| Repairing paint imperfections | Car body surface, scratches | Gel Swabs | Apply the repair product, which can precisely control the amount to avoid too much friction on the car paint. |

5. Medical and first aid

| Cleaning tasks | Items | Suitable types | Instructions |

| Cleaning and disinfecting wounds | Skin wounds, abrasion sites | Non-woven Swabs | Non-woven swabs have good adsorption and can gently clean and disinfect wounds to avoid secondary infections. |

| Applying medication or disinfectant | Skin surface, wounds, injection sites | Foam Cleaning Swabs | Foam cleanroom swabs are soft and suitable for precise application of medication without irritating the skin. |

| Precision instrument cleaning | Medical instruments, first aid tools, needles, etc. | Microfiber Swabs, Polyester Swabs | Low flaking, non-static design, suitable for cleaning precision medical equipment to avoid instrument contamination. |

| Sterilization of electronic equipment | Medical equipment screens, sensors | Static Control Swabs | Anti-static material protects sensitive equipment and prevents static buildup from damaging electronic equipment. |

| Cleaning and Sterilizing Mouth, Teeth | Internal oral cavity, teeth cleaning | Non-woven Swabs, Gel Swabs | Ideal for delicate cleaning and medication application to ensure effective cleaning and avoid injury to sensitive areas. |

6. Arts & Crafts

| Cleaning tasks | Items | Suitable types | Instructions |

| Cleaning and restoration of canvas details | Canvas, oil, acrylic | Polyester Swabs, Microfiber Swabs | Low flaking and highly absorbent, suitable for removing dust and tiny stains without damaging the surface of the canvas. |

| Applying and mixing paints | Small areas of paint, retouching details | Foam Cleaning Swabs | Foam cleaning swabs are soft and suitable for applying paint or mixing details with precision, avoiding brush marks. |

| Trimming carved details | Wood carving, stone carving, carving small details | Microfiber Swabs | Precision is designed to remove dust and stains from carving surfaces without affecting the details of your work. |

| Cleaning Craft Tools | Brushes, carving knives, paint trays | Non-woven Swabs | Strong adsorption, suitable for cleaning residual pigments on craft tools, removing dust and fine particles. |

| Restoring and polishing metal surfaces | Jewelry, engraved pieces, craft metal surfaces | Static Control Swabs | Anti-static, suitable for polishing fine metal surfaces without leaving static and flakes, keeping the luster of the metal. |

7. Laboratory Cleaning

| Cleaning tasks | Items | Suitable types | Instructions |

| Cleaning surfaces of laboratory equipment | Microscope lenses, centrifuges, Petri dishes | Microfiber Swabs | Low-dust fall design removes dust and fingerprints without damaging delicate surfaces. |

| Remove chemical reagent residue | Test tubes, beakers, measuring cylinders | Polyester Fiber Swabs | Chemical-resistant, effectively removes stubborn reagent residue without leaving residue. |

| Cleaning electronic lab equipment | Electronic microscopes, sensors | Static Control Swabs | Antistatic material to protect precision electronic equipment from static buildup. |

| Remove grease or tiny particles | Optical lenses, microscope slides | Foam Cleaning Swabs | Foam material is highly absorbent and gently removes grease and fine particles without scratching the surface. |

| High-precision cleaning of sensitive surfaces | PCR equipment, micropipettes | Non-woven Swabs | Adsorbent gently removes tiny residues, suitable for daily cleaning and maintenance. |

How to use cleanroom swabs properly for cleaning?

1. Be gentle with precision parts

Avoid using too much force when cleaning with cleanroom swabs may cause damage to the surface of precision parts, always use the minimum force to clean.

2. Follow the surface

In the wiping process, by the direction of the smooth wipe, rather than back and forth friction, repeated friction will lead to stains being rubbed deeper, and even on the surface of the subtle damage.

You can also choose to change the direction or gently wipe in a circular or spiral line to avoid improper operation and damage to the surface of the object.

3. Choosing the right cleaning solution

Choose to use a cleaning solution that is compatible with the composition of the cleanroom swab to avoid chemical reactions that may damage the cleaning surface or reduce the cleaning effect.

Gently dipped cleaning fluid, too much liquid may penetrate the sensitive parts of the equipment, resulting in corrosion and damage. Appropriate cleaning agents can help swabs to remove grease and dirt, but too much is counterproductive.

4. Ensure a clean and dust-free environment

In a highly clean environment, the use of cleanroom swabs as far as possible to choose to operate in a closed space helps to isolate the dust and particles in the external environment.

Operating in a closed space and with strict control of the environment, can minimize the impact of outside contamination on the cleaning task, maintain the stability of the high cleanliness environment, to ensure that the cleanliness of equipment, products, and operations is in line with the requirements.

This is especially important for the cleaning of highly precise equipment (e.g., electronic components, optics, semiconductors, etc.), where any minute amount of dust and particles may cause damage or degradation of performance.

5. Check the condition of the swabs

When using cleanroom swabs in the cleaning process, you need to check the condition of the swabs promptly. If the swab head is found to be dirty, this means that it needs to be replaced with a new swab. Continuing to use such swabs that are stained or impregnated with liquids can lead to secondary contamination.

Conclusion

We hope that based on this guide you will be able to find the cleaning industrial cleanroom swabs that meet your needs, whether it's the material of the swabs, the size, or the compatibility with chemical solvents, we will provide you with professional support.

As a professional manufacturer and supplier of cleanroom swabs, we are committed to providing a wide selection of swabs to keep your business fully operational.

With more than 10 years in the industry, we understand the special requirements of each industry in the cleaning process, whether the application is for electronic equipment, fiber optics, automotive, cosmetics, etc., we can provide you with customized solutions to obtain quality standards while gaining good cost control.