We often forget about the simple swab in our cleaning kit. Yet, it plays a big role in keeping places sterile. Places where even a tiny speck of dust could cause big problems. A lint free swab isn't just another tool. It's a vital helper in our fight against unseen enemies that could harm cleanroom spaces.

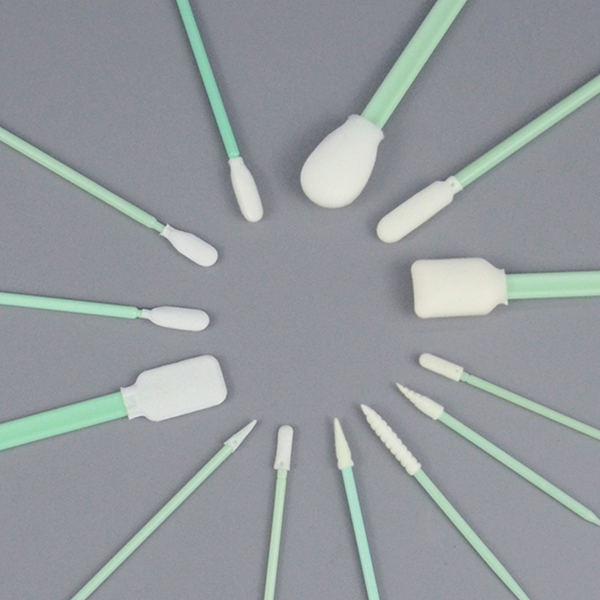

These special swabs are made to not let go of fibers or particles during use. This is very important. It helps stop contamination in sensitive spots like aerospace factories, biotech labs, and places where medicines are made. With prices ranging from $7.99 to $709.9912, and being made in different countries like China, the USA, Japan, and Costa Rica1, it's clear that these swabs come in many types. Each serves different needs in various industries.

Key Takeaways

- Lint-free swabs prevent contamination in cleanroom environments.

- Various materials like polyester, foam, and cotton are used for swab tips1.

- Swabs come in diverse sizes, from 2.7 inches to 6 inches in length1.

- The availability of swabs ranges widely in pack sizes and price points12.

- Certain swabs are ISO-classified for specific cleanroom applications1.

- Technological innovation evolves the production and features of lint-free swabs2.

- Specialty swabs including ESD protection options cater to unique industrial needs2.

Understanding the Basics of Lint Free Swabs

When we talk about keeping places spotless, lint-free disposable swabs are key. They're made carefully to stop tiny dust from spoiling clean areas.

The Importance of Lint-Free

In places like cleanrooms, even a little lint is a big problem. Lint-free swabs are crucial in stopping such dust. The PurSwab swabs are made to keep lint and residue away. They help keep clean spaces pure and work consistently.

Using swabs that don't shed, places can keep contamination low. This ensures cleanliness and steady operations.

Characteristics of High-Quality Lint-Free Swabs

Top-notch lint-free swabs capture particles well and are made for precision. They come in various materials like cotton and microfiber for specific needs3. Microfiber swabs, for example, are great for sensitive tasks. Foam swabs are preferred for general cleaning for their trapping and non-linting features3.

Common Materials Used in Lint-Free Swabs

The swabs are made from different materials to fit specific needs. Swab shafts can be wood, polypropylene, or paper, each offering unique benefits3. The tip material is also key. For instance, polyester swabs are soft for cleaning delicate electronics3.

Lint-free swab prices vary widely, from $6.99 to $699.99. This reflects the range in their types and uses2. With options for general or critical uses like cleanrooms, there’s something for every need2.

Types of Lint-Free Swabs and Their Uses

Using the right tools is crucial in precision cleaning and sensitive tasks. Lint-free swabs are key because they are versatile and prevent contamination. They are made for different jobs in many industries.

Sterile swabs are essential in places like hospitals and labs where everything must be germ-free. Each swab is packed separately and treated with gamma rays to kill germs. Disposable swabs are easy to use once and throw away, lowering germ spread risks. They often come ready with IPA (Isopropyl Alcohol) for quick use.

| Type of Swab | Main Use | Typical Price Range |

|---|---|---|

| Double Pointed Tip Cotton Swab | Precision cleaning, application of adhesives | $17.99 - $89.994 |

| Micro denier Covered Foam Swab | Electronics and cleanroom applications | $10.99 - $219.994 |

| Microdenier Covered Foam Swab | Delicate surfaces, sensitive optics cleaning | $22.99 - $219.904 |

5Lint free swabs are made from materials like polyester and foam. These materials don't leave behind fibers or bits. Cleanrooms need specific swabs to meet cleanliness standards5.

The Elongated Tip Knitted Polyester ESD Swab meets the needs of static-sensitive areas. It helps where electrostatic discharge could cause problems.

The average price of a lint free swab is about $38.425. They come in many sizes for tasks from automotive care to aerospace engineering.

Choosing the right lint-free swab ensures the best results for each task. Their ability to be used once and thrown away makes them essential in many fields.

Lint Free Swab, Lint Free Cleaning Swabs, Cleanroom Swab

In today's accuracy-focused industries, the correct tools are crucial. Lint-free swabs and cleanroom swabs play a key role in keeping environments free from contaminants.

Defining Cleanroom Swabs and Their Applications

Cleanroom swabs must meet strict cleanliness standards. They're vital in areas where creating minimal particles is necessary. Made from long fibers like polyester or microfiber, they leave behind little residue.

They're especially helpful in places like pharmaceuticals, biotech, and making electronic devices.

Cleanroom swabs come in various tip sizes to clean around small parts. You can find them in sizes from 0.125" to 0.264". They are available in quantities from 10 to 500 to suit various needs6.

Why Lint-Free Cleaning Swabs Are Essential for Precision Cleaning

For precision cleaning, lint-free swabs are a must-have. They're crucial in fields where any contamination can cause big problems. Whether for removing particles or applying solutions, these swabs leave no residue. This is vital in making electronics and in labs.

Cotton and foam tips make up many lint-free swabs, showing their wide use6. Prices range from $6.99 to $699.99, giving options for various budgets and needs2.

The Evolution and Innovation in Lint-Free Swab Technology

Lint-free swab development has improved greatly over the years. This progress is driven by the need for better cleaning capabilities. Now, these swabs come in cases of 1,000 to 12,000, offering lots of choices for users6.

New packaging strategies, like double-packing, protect swabs from contaminants. This helps keep them clean until use.

To conclude, picking the right lint-free and cleanroom swabs is crucial in precision cleaning industries. The ongoing improvements in swab technology show dedication to better cleaning needs.

How to Choose the Right Lint Free Swab for Your Needs

Choosing the right lint free swab involves considering several factors. These ensure top performance for precision cleaning and keeping areas sterile. Your choice affects cleanliness, integrity, and the functionality of critical spaces and sensitive gear.

There are many lint free swabs for different sectors like biotech, aerospace, and electronics. Cleanliness is crucial in these fields. For example, electronics favor foam swabs for their absorbency and gentleness, while biotech goes for knitted polyester due to low particle release7.

Swab material is key—cotton, foam, or polyester, each suits specific needs. Foam is great for solvent cleaning or sample collection. Polyester stands up to tough chemicals7.

| Swab Type | Common Uses | Benefits |

|---|---|---|

| Knitted Polyester | Pharmaceutical Manufacturing | Low particle and fiber release |

| Foam | Electronics and Aerospace | Excellent solvent absorption, non-abrasive |

| Cotton | General Purpose | Economical, versatile |

| Microfiber | Optical Lenses and Instruments | Superior cleaning efficiency |

The size and shape of the swab are also crucial. They must fit the area without causing contamination. Swab shafts differ too, from sturdy plastic to flexible paper7.

In places like hospitals or labs where sterile swabs are a must, you cannot compromise on cleanliness. Items like PurSwab's 3" Lint Free Double-Ended Mini-tip Cotton Swab are perfect for precise, hygienic tasks7.

The choice of lint-free swab depends on the needs of your environment and what you need to clean. By considering these aspects, professionals can maintain cleanliness and functionality. This is vital in sensitive areas where even small amounts of contaminants have big effects7.

Lint Free Swabs in Various Industries: From Healthcare to Electronics

Lint free swabs are essential in many fields. Each has its requirements that the swabs must meet. They are used for precise cleaning and controlling contamination in important areas. This includes medical places and technology manufacturing sites.

Healthcare: The Role of Sterile Swabs

For healthcare, healthcare sterile swabs are very important. They are used in many medical tasks, from testing to treatments. These swabs help collect samples cleanly, are key for correct test results, and keep patients safe. They must be sterile to avoid any infections or spreading germs.

Electronics: Precision Cleaning Swabs and Their Significance

In electronics, electronics precision cleaning swabs keep things working right. These special swabs take away tiny bits that could cause big problems. Making sure parts are clean helps stop them from breaking down. This is super important when making very small electronics.

Industrial Applications: Durability of Industrial Cleaning Swabs

Industrial cleaning swabs are key in making things. They're used for putting on solvents or glues and taking off dirt from machines. They're tough enough to not break down with strong chemicals or in hard use.

These swabs come in sizes from 3 to 9 inches for precise work in different settings2.

The wide range in prices and packaging of lint free swabs shows their use in many areas. Harmony Lab has 52 different cleanroom swabs. Their prices go from $6.99 to $199.99 per pack. This fits various budgets and needs2. On the other hand, Puritan Medical Products offers a high-end option. Their Puritan Folded Tip Knitted Polyester Swab costs $699.99. It has special features for very important jobs2.

Lint free swabs are made with great materials and designs. They are built to high standards. This makes them vital for work and safety in several industries. Each swab type, whether for health, electronics, or industry, is made to be reliable and effective.

Conclusion

In our talks, we've looked at how important lint free swabs are in many industries. These industries have strict cleanliness standards. Swabs like Coventry™ polyester are washed in cleanrooms to keep them pure. This helps with effective cleaning in sensitive areas8. The journey from the first cotton swab made in 1893 to today's advanced options shows a growing understanding. It shows how crucial it is to reduce contamination and manage hygiene well9.

Materials like knitted polyester are made to meet the needs of industries that can't handle contamination. Lint free cleaning swabs, including foam types, work really well in cleanrooms and other places8. We also see new swabs being made, like those that control static. They are used when making or fixing electronic devices8.

To keep things running smoothly, choosing the right swab is key. Knowing about the different swabs and their uses helps us improve our work quality. Swabs are critical in keeping equipment in good shape in electronics, healthcare, and cleanrooms. They help things last longer and keep everyone safe89. By changing swabs often, we stop old dirt from causing problems. This keeps our workspaces clean and our processes accurate8.

FAQ

What is a lint free swab?

A lint free swab is a special cleaning tool. It doesn’t release fibers or particles when used. This is very important in places that must be very clean and precise. These swabs clean very carefully and accurately.

Why are lint free swabs important?

Lint free swabs are vital for keeping certain areas free from contamination. They don’t shed any material. This makes them perfect for clean spaces and precise jobs.

What are the characteristics of high-quality lint free swabs?

Good lint free swabs are extremely clean, capture particles well, and help you control their use precisely. They won’t shed and don’t make many particles. They’re great for detailed work.

What materials are commonly used to make lint free swabs?

They often use low lint cotton and open-cell foam to make lint free swabs. These materials don’t create many particles, making them great for delicate cleaning jobs.

What types of lint free swabs are available?

You can find different lint free swabs like sterile, for precise cleaning, and for industrial use. They vary in tip shapes, shaft materials, and how much they can soak up. This helps them fit various needs in healthcare, electronics, and industry.

What are cleanroom swabs and where are they used?

Cleanroom swabs don’t shed and hardly make any particles. They’re used in cleanrooms for industries like drug making, electronics, and biotech. These places need very high cleanliness levels.

Why are lint free cleaning swabs essential for precision cleaning?

For precision cleaning, lint free swabs are key. A tiny bit of lint or dirt can cause big problems. This could ruin samples, mess up manufacturing, or break electronics.

How has lint free swab technology evolved?

Lint free swab tech has gotten better to meet strict cleanliness needs. Newer and better materials, additional packing for less contamination, and special tip shapes have been developed.

How do I choose the right lint free swab for my needs?

Think about the swab’s material, absorbency, size, and shape. Match these features with your job’s needs, like being very precise, needing to be sterile, or being strong.

In what industries are lint free swabs crucial?

Lint free swabs are key in healthcare for keeping things sterile, in electronics to keep things clean and working, and in industry where they must be strong against tough conditions and chemicals.